Kit Electronics

The AliExpress kit comes with Nema23 Steppers, DM542 Drivers, Mach 3/LinuxCNC compatible breakout board and a 36v Power supply. This is a great starting point for your build and provides very good performance at a reasonable price

There currently isn’t a comprehensive guide for configuring the electronics, however the PrintNC use identical concepts as other CNC machines available and there is plenty of great resources available online

The PrintNC Wiki has a rapidly developing electronics guide and is an excellent reference

https://wiki.printnc.info/en/home

Low Cost – Nema 17 Upgrade

An option for someone upgrading from an existing Nema 17 machines to a PrintNC is an Arduino Mega, Ramps 1.4 board (modified), DRV8825 Drivers and a 24volt power supply as this is the lowest cost solution that provides good performance.

It is vital that any alternative driver boards (eg. Rumba) are at least 24v or higher

Do not connect the power supply until this is done

Active Cooling Fan is Critical when running RAMPS at 24-30v!

Stock Ramps boards will only allow a max voltage of 12v. Higher voltage results in higher speed. In order for the steppers to run at high enough speeds the PrintNC requires a minimum of 24volt

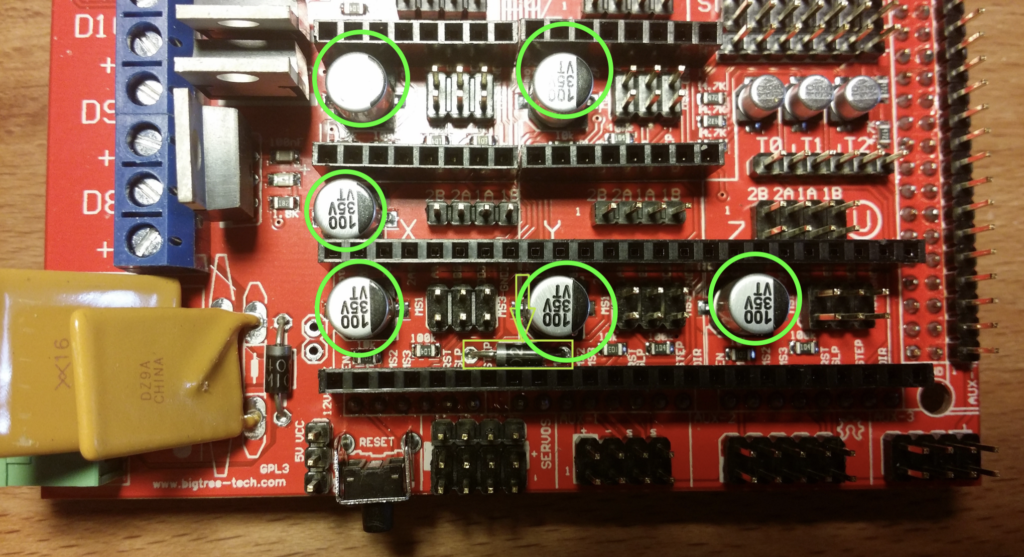

First step is to check that your Ramps board is capable of running at 24v by checking these diodes are 35v or higher, most boards from China will be 35v but some may be 16v, unfortunately if your board has 16v capacitors it will not be usable.

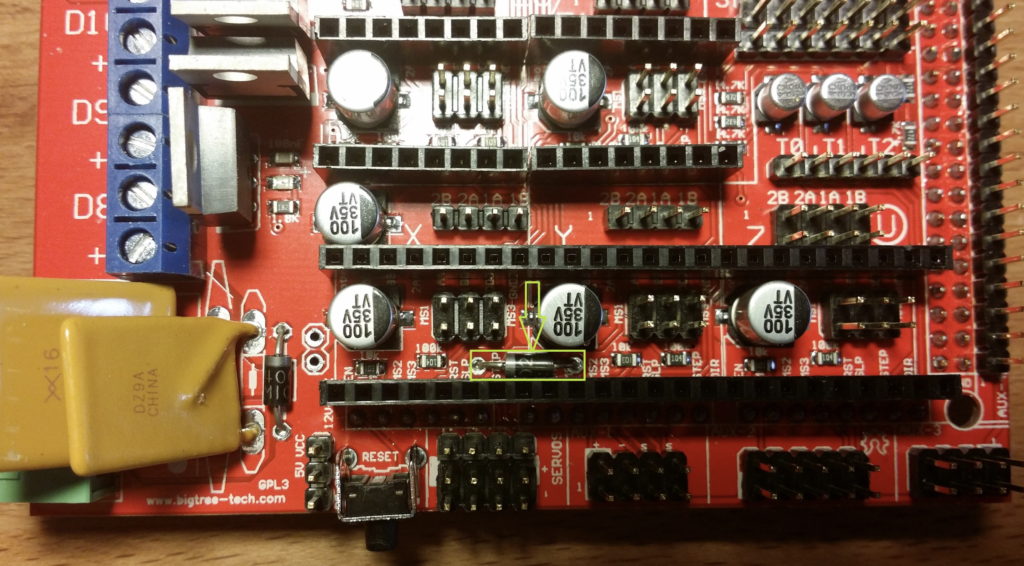

Once you have checked the capacitors remove the D1 Diode

There is no reason to fear doing this as the D1 Diode simply provides power to the connected Arduino for USB free operation.

As this is a CNC and not a 3d printer you will always need to have a computer connected to the USB for controlling and positioning the origin and as such this is of no consequence.

Modification complete.

Setting Jumpers

Ramps uses jumper settings to set the microstep value. The PrintNC uses 1/2 stepping in order to maximise torque and still provide smooth motion. Due to the gear reduction effect of the 1605 Ball Screw